*CLEARANCE* (EXPIRED ON 07/22) Yamamoto Nutrition BCAA 8:1:1 200 Caplets

ProteinLab sports supplement supplier/wholesaler Malaysia presents!

*CLEARANCE* (EXPIRED ON 07/22) Yamamoto Nutrition BCAA 8:1:1 200 Caplets!!

Be safe and rest assured you are getting 100% authentic products at the lowest price when you purchase from ProteinLab Malaysia.

You can also like our Facebook for more promotion news at :

Or you can also follow Instagram for more nutrition tips:

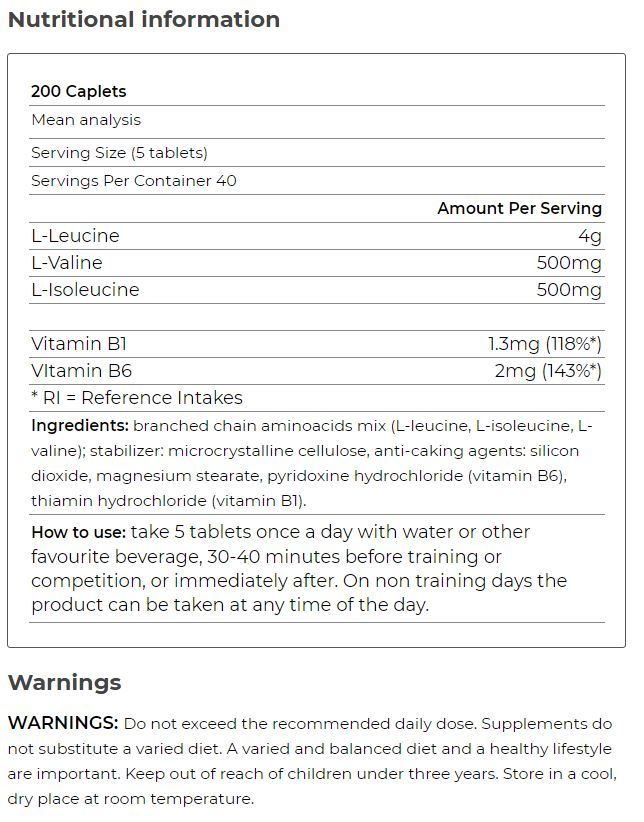

Proteinlab Malaysia presents Yamamoto Nutrition BCAA 8:1:1 200 caplets. BCAA 8:1:1 is a food supplement of branched-chain amino acids with vitamins B1 & B6.

BCAA are essential amino acids to the body that is indeed unable to synthesize them & must therefore be ingested through the diet. BCAA 8:1:1 is made from 1000mg tablets in the innovative ratio 8:1:1 (Which is 8 parts of L-Leucine, 1 of L-Valine & 1 of L-Isoleucine). The branched-chain amino acids are indicated to supplement the diet of athletes who train every day. Along with that, the formula includes vitamin B1 which supports normal energy metabolism plus vitamin B6 which helps to reduce fatigue, and tiredness & supports the normal metabolism of protein & glycogen.

Why is Yamamoto Nutrition BCAA 8:1:1 is Superior to most BCAA?

Every Yamamoto Nutrition has improved the formula by separating the whey with High Wind Pressure Spray Drying instead of the traditional Boiling.

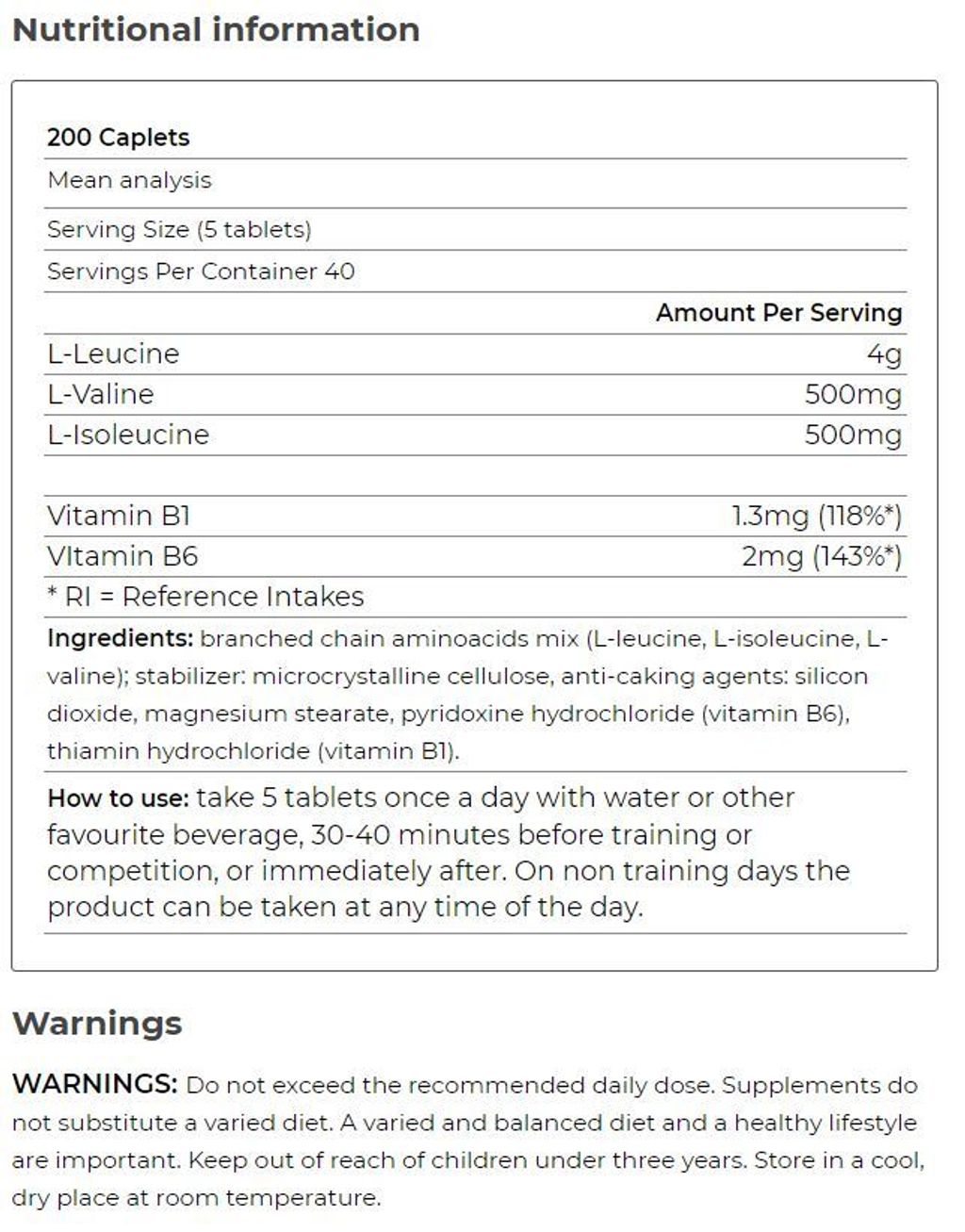

Spray drying is rapidly becoming the preferred technique for a growing number of pharmaceutical companies to produce Top Quality Powder in order to maintain most, if not, ALL of the minerals where else the boiling has a high risk of over-boiling it.

Despite being very commonly used in the food and chemical industries for decades, spray drying has, until quite recently, only been a niche technology in pharmaceutical manufacturing. In fact, until the 1980s, drug companies tended to favor easy-to-process molecules — so-called BCS 1 substances — that inherently demonstrated good solubility and permeability properties.

When the medical community’s focus shifted to diseases such as AIDS, however, poorly soluble molecules could no longer be ignored. Providing the ability to form solid dispersions, spray drying appeared to offer a solution. Yet, even though the industry was now able to enhance the solubility and, consequently, the bioavailability of BCS 2 drugs, some remained unconvinced.

Concerns centered on the notion that the high temperatures applied during spray drying would denature delicate pharmaceutical substances, notwithstanding the fact that many proteins — and even enzymes — are successfully spray dried in the food industry!

The spray drying process

As a technique, spray drying consists of three basic stages:

Atomization

The liquid feedstock is “atomized” into droplets using a nozzle or rotary atomizer. Nozzles use pressure or compressed gas to atomize the feed whereas rotary atomizers employ an atomizer drum rotating at a high speed

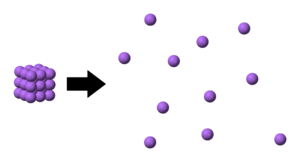

Drying and particle formation

Guided by a gas disperser, hot process gas (air or nitrogen) is brought into contact with the atomized feed, initiating evaporation. As the liquid rapidly evaporates from the droplet surface, solid particle forms and fall to the bottom of the drying chamber. The balance between temperature, flow rate, and droplet size controls the drying process

Recovery

The powder is recovered from the exhaust gas using a cyclone or a bag filter. The whole process typically takes no more than a few seconds.

In summary

This ultrafast and gentle drying technology offers unique ways to define particle characteristics and enable the development of novel formulations and delivery systems that were previously unattainable. And, because spray drying is a continuous process, it offers both high productivity and uniform product quality during sustained periods.